Understanding R404a and Its Phaseout

R404a is a common hydrofluorocarbon (HFC) refrigerant blend used in commercial refrigeration applications, such as supermarket display cases, refrigerated transport, and ice machines. However, due to its high Global Warming Potential (GWP), R404a is being phased out globally. Common alternatives include R448A, R449A, and R452A, each with a lower GWP and potentially improved energy efficiency. While these alternatives are becoming more prevalent, many R404a systems are still in operation, making understanding its properties and the proper handling procedures crucial.

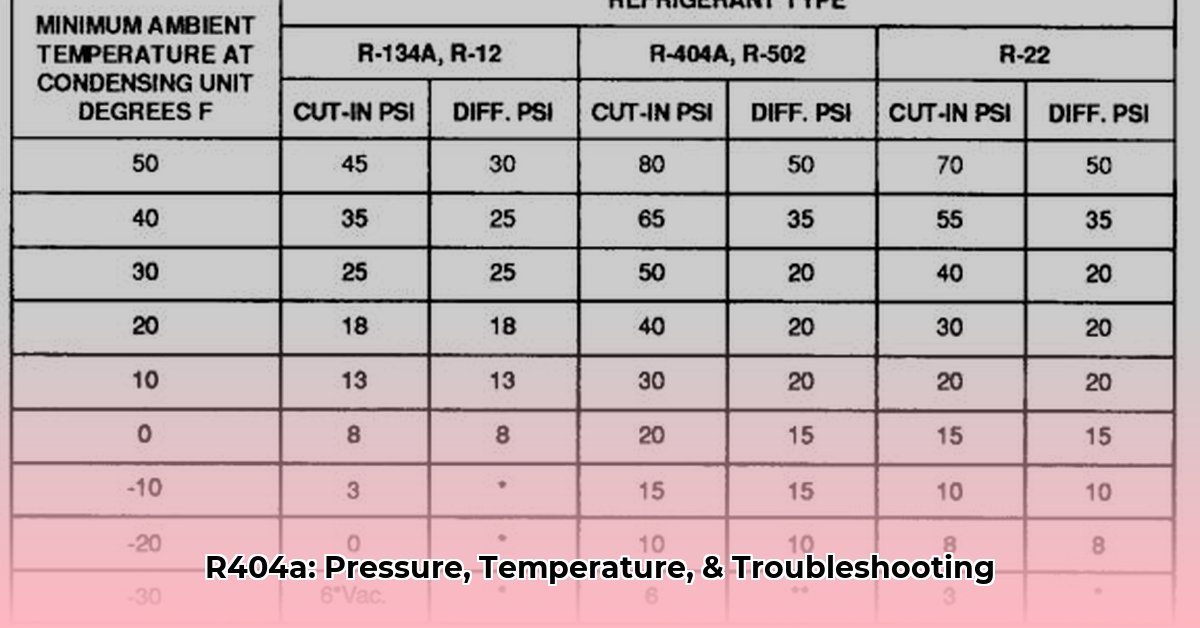

Using the R404a P-T Chart

The pressure-temperature (P-T) chart is a fundamental tool for anyone working with R404a. It visually represents the relationship between the refrigerant’s pressure and its temperature in a saturated state (a mixture of liquid and vapor). This relationship is a key indicator of system health and performance.

How to Interpret the Chart

The R404a P-T chart typically displays pressure on the vertical axis (in both pounds per square inch gauge [psig] and kilopascals [kPa]) and temperature on the horizontal axis (in both degrees Fahrenheit [°F] and degrees Celsius [°C]).

-

Temperature to Pressure: To find the expected pressure at a given temperature, locate the temperature on the horizontal axis. Draw a vertical line upwards until it intersects the R404a saturation curve. The corresponding pressure can then be read from the vertical axis.

-

Pressure to Temperature: Conversely, to find the expected temperature at a given pressure, locate the pressure on the vertical axis. Draw a horizontal line across until it intersects the R404a saturation curve. The corresponding temperature can be read from the horizontal axis.

R404A Pressure-Temperature Chart (PSI, °F and kPa, °C) – Sample Values

| Temperature (°F) | Pressure (psig) | Temperature (°C) | Pressure (kPa) |

|---|---|---|---|

| -40 | 11 | -40 | 76 |

| -20 | 21 | -29 | 148 |

| 0 | 36 | -18 | 245 |

| 20 | 55 | -7 | 376 |

| 40 | 79 | 4 | 547 |

| 60 | 111 | 16 | 765 |

| 80 | 150 | 27 | 1035 |

[!NOTE]

This table provides estimated values for illustrative purposes. Always consult a comprehensive, certified R404a P-T chart for precise data. Downloadable versions are often available from refrigerant manufacturers or industry organizations like ASHRAE.

Applying the Chart for Superheat and Subcooling Calculations

The P-T chart is essential for calculating superheat and subcooling, vital parameters for system optimization:

- Superheat: Superheat = Actual Vapor Temperature – Saturation Temperature (at the same pressure)

- Subcooling: Subcooling = Saturation Temperature (at the same pressure) – Actual Liquid Temperature

Superheat ensures only vapor enters the compressor, while subcooling ensures liquid refrigerant enters the expansion valve. Deviations from optimal superheat and subcooling values can indicate system inefficiencies or malfunctions.

Troubleshooting with the P-T Chart

Discrepancies between observed pressure and temperature readings and the P-T chart often indicate system issues. While there might be other factors at play, the P-T chart is a crucial first step to diagnose common problems:

- Low Pressure: This may suggest an undercharge, a refrigerant leak, restricted airflow, or a failing compressor.

- High Pressure: This might indicate an overcharge, a blocked condenser coil, non-condensables in the system, or compressor valve issues.

- Fluctuating Pressures: This could point to a significant leak or imminent compressor failure.

Safe Handling of R404a

R404a requires careful handling due to potential health and environmental risks.

- Ventilation: Always work in well-ventilated areas to prevent oxygen displacement and minimize inhalation risks.

- Personal Protective Equipment (PPE): Use gloves and eye protection to prevent skin and eye irritation.

- Recovery and Recycling: Never vent R404a into the atmosphere. Recover and recycle the refrigerant using approved equipment and procedures in accordance with local regulations.

- Cylinder Disposal: Dispose of empty cylinders properly through authorized channels. Consult local waste management regulations.

[!IMPORTANT]

Only certified technicians (e.g., those with EPA Section 608 certification in the US) should handle refrigerants. Always adhere to relevant safety regulations and manufacturer guidelines.

Transitioning to R404a Alternatives

The future of refrigeration involves refrigerants with lower GWP. R448A, R449A, and R452A are some of the leading alternatives to R404a. While these refrigerants offer environmental benefits, it’s important to recognize that each has its own unique properties and requires specific handling procedures. Consulting a manufacturer’s documentation for the chosen alternative refrigerant is essential to ensure compatibility and safe operation. Some system modifications might be necessary. This transition also requires HVAC-R technicians to stay updated on the latest developments and best practices for handling these newer refrigerants. Ongoing research suggests that further advancements in refrigerant technology are likely, so continued learning is paramount.

Additional Resources

- ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) provides valuable resources and standards for the HVAC&R industry, including information on refrigerants and their properties.

- EPA (Environmental Protection Agency) offers regulations and guidelines related to refrigerant handling and disposal in the United States.

Disclaimer: This information is for general guidance only. Consult with a qualified HVAC/R technician for system-specific advice, maintenance, and refrigerant handling.

- How to Produce Free Energy for Your Home - February 11, 2026

- How to Generate Electricity for Free at Home - February 10, 2026

- How To Produce Free Electricity By Generating Your Own Power - February 9, 2026

![R410A PT Chart (Pressure-Temperature Chart): Updated [Year] r410a_pt_chart_edited](https://txgenco.com/wp-content/uploads/2025/04/r410a_pt_chart_edited-150x150.jpg)