Want to make tons of a super-useful enzyme called BglA? It’s key to many biotech breakthroughs, like making biofuels and new materials. This guide shows you exactly how to do it right – from making sure you get a high yield to avoiding common problems when you clean it up. We’ll walk you through the best ways to get BglA working in E. coli bacteria and B. subtilis, sharing tips and tricks from experts and the biotech community. Plus, we’ll help you plan for the future and stay on top of all the rules and regulations, so your BglA projects stay ahead of the curve. For advanced plasma applications, see this resource.

BglA: Unlocking the Potential of a Biotech Powerhouse (Thermostable Beta-Glucosidase)

BglA, a heat-loving enzyme from bacteria like Clostridium thermocellum, and other microbial sources, is making waves in biotechnology. Specifically, BglA is a type of beta-glucosidase (EC 3.2.1.21), essentially a tiny molecular machine that excels at breaking down cellulose, cellobiose, and related beta-glucosides. Think of it like nature’s super-efficient recycling system for plants, and also a key player in various metabolic pathways.

This ability is incredibly valuable because cellulose is a major component of biomass, which holds enormous potential as a source of biofuels, bioproducts, and other useful compounds. The fact that some BglAs thrive in high temperatures represents a significant advantage for industrial applications, enabling faster reaction rates and increased efficiency.

The Challenges of Getting More BglA: Expression Yield Optimization

While producing BglA in microbial hosts like E. coli (a common workhorse of biotechnology) and B. subtilis shows great promise, challenges remain in achieving consistently high yields and purity. The yield – the amount of BglA we get compared to the effort put in – can vary significantly depending on the production method, expression system, and fermentation conditions. This inconsistency is a major hurdle in making BglA widely available and cost-effective. Researchers are actively working on refining the purification process and optimizing expression strategies to create protocols that consistently deliver large quantities of high-quality BglA, making production both predictable and efficient.

A Step-by-Step Guide to Better BglA Production (Fermentation Process)

Creating BglA isn’t a simple recipe; it’s a carefully orchestrated process. Here’s a more detailed, multi-faceted approach:

-

Strain Selection and Engineering: The first step involves selecting a suitable host organism (E. coli, B. subtilis, yeast, or even cell-free systems) and engineering it for optimal BglA production. This might involve codon optimization of the bglA gene, promoter engineering, and deletion of competing pathways. The choice of expression system also depends on the specific BglA variant and its origin.

-

The Expression System: Fine-Tuning the Genetic Switch: This involves using a smart gene control system – an inducible promoter – within the chosen host strain. Strong, tightly regulated promoters like the lac promoter, tac promoter, or T7 promoter in E. coli, or the xylA promoter in B. subtilis are commonly employed. The inducer concentration, timing, and duration are carefully optimized. Co-expression of chaperone proteins can assist in proper folding of the BglA enzyme, especially for thermophilic variants.

-

Finding the Sweet Spot: Optimizing Fermentation Conditions: Microbes are sensitive creatures. To get the best BglA yield, researchers carefully adjust factors like temperature, pH (controlled by automated addition of acid or base), dissolved oxygen levels (maintained by agitation and aeration), and nutrient feed rates. Sophisticated fermentation strategies, such as fed-batch or continuous culture, can further enhance BglA production. Furthermore, optimizing the carbon source (glucose, lactose, glycerol), nitrogen source (ammonium salts, amino acids), and trace element composition can boost BglA production. Foam control is also critical in large-scale fermentations.

-

Cell Disruption and Initial Recovery: After fermentation, the cells are harvested and disrupted to release the BglA enzyme. Common methods include sonication, mechanical disruption (e.g., bead milling, high-pressure homogenization), or enzymatic lysis. Following cell disruption, cell debris is typically removed by centrifugation or microfiltration.

-

Purification: Separating the BglA from the Crowd: Once the bacteria have produced plenty of BglA, the next challenge is isolating it from everything else inside the cells, which can be a complex process. A combination of techniques is often used. Heat treatment can selectively denature and precipitate contaminating proteins, while BglA remains stable (due to its thermostability). Ammonium sulfate precipitation can selectively precipitate BglA. Affinity chromatography, using a ligand that specifically binds to BglA, provides high purity in a single step. Ion exchange chromatography (anion or cation exchange) separates proteins based on their charge. Size exclusion chromatography separates proteins based on their size.

-

Formulation and Stabilization: The purified BglA enzyme is then formulated into a stable form for long-term storage and industrial use. This might involve adding cryoprotectants (glycerol, trehalose) for freeze-drying (lyophilization) or spray-drying. The pH and ionic strength of the formulation buffer are also optimized.

-

Quality Control: Making Sure It Works: Finally, the purified BglA undergoes rigorous testing to check its activity (using enzyme assays with specific substrates), stability (measuring activity over time at different temperatures), and purity (using SDS-PAGE, mass spectrometry, or other analytical techniques) to ensure that it does what it’s supposed to do efficiently.

Expanding BglA’s Toolkit: Genetic Engineering and Versatile Applications

The beauty of enzymes like BglA lies in their potential for improvement. Scientists are busy engineering them—making small changes to their genetic code—to broaden their capabilities using techniques like directed evolution and rational design. This could involve modifying BglA’s active site (the part of the enzyme where the magic happens), improving its thermostability, increasing its activity on specific substrates, or altering its pH optimum. This expanding versatility will significantly enhance its usefulness in biofuel production (hydrolyzing complex carbohydrates in biomass, reducing end-product inhibition by removing cellobiose), bioproduct synthesis, and open doors to other applications we haven’t even imagined yet.

BglA in the Real World: The Future is Now (Almost) (Industrial Biotechnology)

BglA has the potential to revolutionize various biotech processes, from biofuel production to the development of new chemicals and materials. Potential applications include:

- Biofuel Production: Improving the efficiency of cellulose hydrolysis during biofuel production.

- Food Industry: Enhancing the flavor and digestibility of food products.

- Textile Industry: Improving the processing of cotton and other cellulose-based fabrics.

- Pharmaceutical Industry: Synthesizing novel glycosides and other bioactive compounds.

However, large-scale industrial implementation requires addressing several challenges. The cost of enzyme production, the long-term stability of BglA in industrial environments, and the potential for enzyme inhibition by reaction products need to be carefully considered.

Different Perspectives on BglA: Who’s Involved? (Stakeholder Goals)

| Stakeholder | Short-Term Goals | Long-Term Vision |

|---|---|---|

| Biotech Companies | Streamlined purification; reliable testing methods | Large-scale cost-effective production; diverse applications |

| Researchers | Understanding BglA’s mechanisms; enhanced variants | Predictive models; highly customizable enzyme engineering |

| Regulatory Agencies | Safety guidelines; rigorous standards | Robust risk assessment; comprehensive monitoring systems |

| Biofuel Producers | Efficient cellulose conversion; reduced costs | Sustainable and economically viable biofuel production |

| Bioproduct Companies | Novel enzyme applications; improved processes | Development of new bioproducts and bio-based materials |

Managing the Risks: Being Prepared (Risk Assessment)

Proactive risk assessment is paramount for safe and effective BglA implementation.

| Risk Category | Risk Level | Mitigation Strategy |

|---|---|---|

| E. coli Expression | Low | Employ safe strains; maintain strict containment procedures; use auxotrophic strains. |

| Purification | Medium | Optimize protocols; ensure the safety of all reagents; use validated cleaning procedures. |

| Industrial Application | Medium | Comprehensive risk assessments; adhere to regulations; implement proper containment measures. |

| Unintentional Release | High | Thorough environmental monitoring; strategies for enzyme inactivation; genetically modified organisms with limited survival capacities. |

BglA holds incredible promise for various biotechnological advancements. While exciting breakthroughs are on the horizon, continued research and development are vital to fully unlock the potential of this remarkable biotech workhorse.

Optimizing Beta-Glucosidase Purification Yields for Industrial Applications (Downstream Processing)

Key Takeaways:

- High-yield BglA production is achievable, but purification remains a bottleneck.

- E. coli and B. subtilis offer distinct advantages and disadvantages as expression systems.

- Process optimization, including alternative expression systems and refined purification protocols, is crucial for cost-effectiveness.

High-yield production of the thermostable beta-glucosidase (BglA

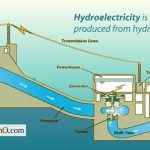

- Is Hydropower Renewable Or Nonrenewable Resource? Sorting Out the Facts - March 3, 2026

- Hydroelectric Power Basics How Water Is Used For Electricity - February 26, 2026

- Portable Water Generators Power Off-Grid Homes and Adventures - February 25, 2026