Want to understand how BMC West plans to succeed in California’s challenging housing market? This report examines their strengths, weaknesses, and strategies for tackling inflation and supply chain disruptions. Consider this your survival guide for BMC West in today’s tough market, providing actionable insights for success. For further insights into navigating market volatility, see this relevant case study.

BMC West: Thriving Amidst 2025’s Housing Market Challenges

The California housing market presents a complex environment, especially concerning California housing market challenges. High prices, fluctuating interest rates, and persistent supply chain issues disproportionately affect companies like BMC West. However, BMC West, a prominent California-based building materials supplier operating within the larger Building Materials Holding Corporation (BMC), possesses distinct advantages to not only survive but thrive.

In-Depth Analysis: Strengths, Weaknesses, and Untapped Opportunities for Building Materials Suppliers

BMC West benefits from a robust reputation within California, fostered by long-standing relationships with contractors and extensive reach throughout the state. Their diversified inventory, encompassing lumber, trusses, doors, and other essential building components, provides a buffer against market fluctuations. This is enhanced by their parent company’s investment in digital tools, notably BuildwithBMC.com, aimed at improving customer connections and streamlining operational efficiency.

However, the scarcity of publicly available financial data presents a challenge in accurately assessing their competitive standing and overall profitability. The tangible impact and adoption rate of the BuildwithBMC.com platform across their customer base also remains unclear. Like their counterparts in the industry, they contend with ongoing supply chain disruptions that elevate costs and limit material availability.

BMC West has significant opportunities for strategic expansion into underserved regions within California. They can also capitalize on the growing demand for sustainable and prefabricated construction solutions by proactively expanding their offerings to include eco-friendly and pre-engineered products. Forming strategic partnerships with innovative technology companies can further drive efficiency gains and unlock new avenues for revenue generation.

Navigating the Gauntlet: Mitigating Risks and Implementing Strategic Recommendations in the Construction Industry

The intensely competitive California housing market, characterized by the presence of large national players exerting considerable pressure on regional operators like BMC West, necessitates a well-defined and meticulously executed strategy, emphasizing supply chain resilience strategies. Prevailing economic uncertainties compounded by persistent supply chain vulnerabilities pose significant threats. These external risks have the potential to detrimentally impact revenue streams and erode profitability margins.

To effectively address these multifaceted challenges, the following strategic plan is recommended:

Short-Term Goals (Next 1-2 Years):

- Digital Integration Optimization: Fully integrate all operational aspects with the BuildwithBMC.com platform to enhance product marketing efforts, elevate customer service standards, and streamline internal processes. Provide training and incentives for both employees and customers to maximize platform adoption.

- Supply Chain Diversification and Fortification: Proactively diversify the supplier network to mitigate vulnerability to potential disruptions. Establish long-term contracts with key suppliers that incorporate built-in flexibility and price protection mechanisms.

- Aggressive Cost Control Measures: Implement stringent cost-cutting measures throughout the organization, with a focus on optimizing inventory management practices, negotiating favorable pricing agreements with suppliers, and identifying areas for enhanced operational efficiency.

Long-Term Goals (3-5 Years):

- Progressive Product Line Expansion: Broaden the existing product portfolio to encompass a wider range of sustainable building materials and prefabricated construction components. Conduct market research to identify emerging customer needs and preferences, tailoring product offerings accordingly.

- Strategic Alliances and Collaborative Partnerships: Cultivate collaborative relationships with technology firms specializing in construction tech and innovative design firms to jointly develop cutting-edge solutions and penetrate previously untapped markets.

- Data-Driven Decision-Making Framework: Invest in advanced data analytics tools and expertise to gain deeper insights into market trends and evolving customer preferences. Leverage these insights to optimize pricing strategies, refine inventory management practices, and personalize marketing campaigns.

The Horizon Beckons: Evaluating BMC West’s Potential for Sustained Success in the Building Sector

BMC West faces considerable headwinds navigating the complexities of the California housing market, especially regarding forecasting California construction market. However, their established market presence, diversified product offerings, and ongoing digital transformation initiatives provide a solid foundation for future growth. Successful execution of the aforementioned strategic recommendations, proactive adoption of emerging technologies, and diligent management of inherent risks will be instrumental in enhancing their long-term prospects. Comprehensive planning informed by a thorough understanding of prevailing market dynamics remains paramount. With the implementation of proactive strategies, BMC West possesses the potential to flourish in the dynamic California building sector.

Mitigating Supply Chain Risks for California Building Materials Distributors

Key Takeaways:

- California’s building materials sector confronts significant supply chain vulnerabilities.

- Proactive and comprehensive risk assessment is paramount.

- Digital tools can dramatically enhance visibility and responsiveness.

- Strategic partnerships and robust inventory management practices are crucial.

- Government policies exert a significant influence on supply chain stability.

Navigating California’s Housing Market Volatility with Robust Supply Chain Management

California’s famously volatile housing market, characterized by fluctuating interest rates, escalating construction costs, and unpredictable demand patterns, mandates the implementation of effective and agile supply chain risk management strategies. This extends beyond simple cost-cutting exercises; it necessitates the development of a resilient and adaptable operational framework.

Identifying Vulnerabilities: A Starting Point for Effective Risk Mitigation Strategies

A crucial first step involves a thorough assessment to define understanding vulnerabilities to risks in building materials sectors. What specific materials are most critical to your operations? Which suppliers have demonstrated consistent reliability? What is the current inventory strategy and how does it align with projected demand? A comprehensive risk assessment, encompassing the identification of potential disruption points and the quantification of their potential impact, is fundamental.

Diversification: Mitigating Concentrated Risk in Construction Supply Chains

Over-reliance on a single supplier exposes businesses to undue risk. Diversifying sourcing strategies by establishing relationships with multiple alternative suppliers and exploring a broader range of materials can significantly reduce dependence on any single point of failure.

Embracing Technology: Leveraging Visibility for Enhanced Supply Chain Resilience

The strategic deployment of technology, incorporating real-time tracking mechanisms and sophisticated inventory management systems, provides unprecedented visibility into the intricate workings of the supply chain, empowering proactive decision-making capabilities. Predictive analytics tools can further enhance this by enabling businesses to anticipate potential disruptions and optimize resource allocation. Consider reviewing how to mitigate supply chain risks for california building materials distributors.

Strategic Partnerships: Fostering Collaboration for Supply Chain Resilience

Cultivating strong, collaborative relationships with key suppliers promotes the open exchange of information, facilitates proactive anticipation of emerging challenges, and fosters the joint development of mutually beneficial solutions.

Inventory Management: Optimizing Stock Levels for Building Supplies

Achieving the optimal balance in inventory levels requires a robust management system that accurately forecasts demand patterns, carefully considers lead times, and incorporates appropriate safety stock buffers.

Government Initiatives and Policy Affecting Construction in California

Staying informed about evolving building codes, stringent environmental regulations, and dynamic trade policies is crucial, as these factors can significantly impact material availability, compliance requirements, and overall costs.

BMC West’s Supply Chain Resilience Strategies in California’s Volatile Housing Market

Key Takeaways:

- California’s challenging housing market requires robust supply chain management.

- Effective strategies must address inflation and interest rate fluctuations.

- A diverse product portfolio is a strategic asset.

- Short-term strategies should focus on optimized inventory management.

- Long-term strategies should emphasize digital transformation across all aspects of the business.

Navigating California’s Housing Rollercoaster: Strategies for Adapting to Volatility

California’s volatile housing market demands considerable operational agility from building material suppliers like BMC West. How can BMC West successfully implement BMC West’s supply chain resilience strategies to thrive in this dynamic environment?

Understanding BMC West’s Position in the California Housing Market

BMC West benefits from its well-established presence and broad product mix, and understanding vulnerabilities to risks in building materials sectors. However, the lack of readily available financial data makes a comprehensive competitive assessment difficult. What is their current market share within key segments?

Analyzing the Risks: A SWOT Framework for Construction Suppliers

Applying a SWOT (Strengths, Weaknesses, Opportunities, Threats) analysis provides valuable insights, and SWOT analysis reveals strengths and weaknesses.

Strengths:

- Extensive regional expertise and pre-existing relationships.

- A highly diversified product portfolio covering a wide array of building materials.

- Strong potential to effectively leverage technology to enhance efficiency and customer experience.

Weaknesses:

- Limited availability of publicly accessible financial information, hindering comprehensive analysis.

- Competitive positioning in specific market segments remains unclear due to data limitations.

- Potential vulnerabilities stemming from reliance on potentially fragile supply chains.

Opportunities:

- Expanding into underserved niche markets with specialized products and services.

- Actively pursuing product diversification to cater to evolving customer preferences.

- Forming strategic partnerships with complementary businesses to expand market reach and service offerings.

Threats:

- Unforeseen economic downturns impacting construction activity and demand for building materials.

- Intensification of competition from both regional and national players vying for market share.

- Persistent supply chain disruptions resulting in material shortages, price volatility, and project delays.

Short-Term and Long-Term Strategies for Building Material Businesses

Short-Term Actions (0-1 year):

- Inventory Optimization: Leverage data analytics to more accurately anticipate demand fluctuations and adjust

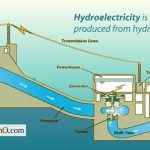

- Hydroelectric Power Basics How Water Is Used For Electricity - February 26, 2026

- Portable Water Generators Power Off-Grid Homes and Adventures - February 25, 2026

- Portable Hydroelectric Power Generators Light Up Off-Grid Living - February 24, 2026