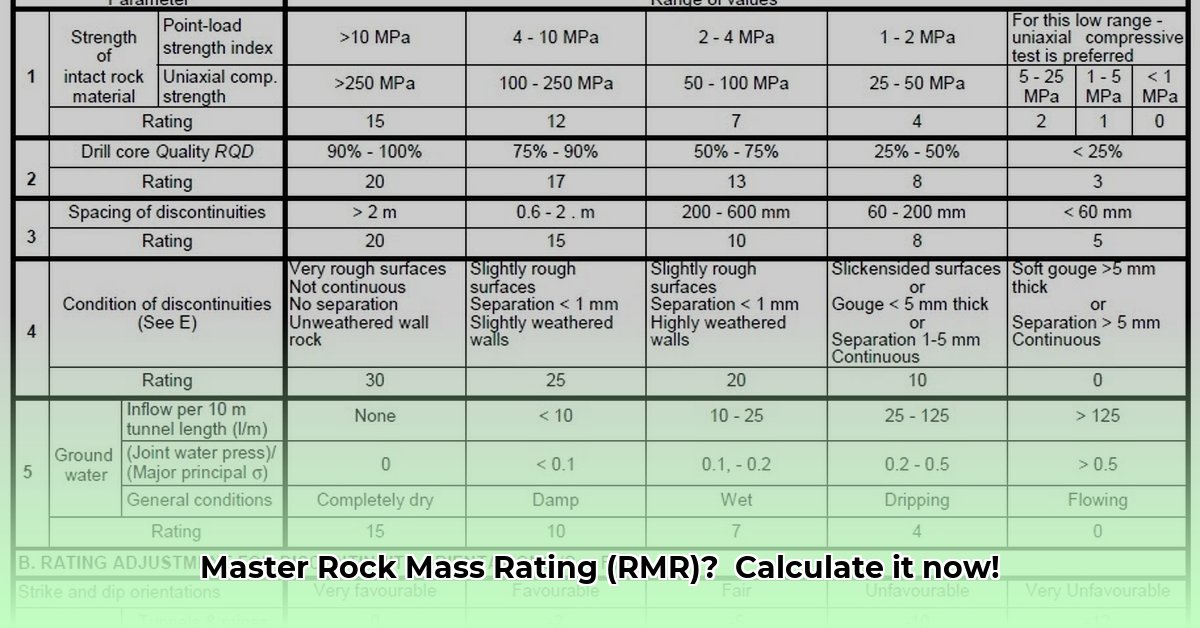

This guide provides a practical, step-by-step explanation of the Rock Mass Rating (RMR) system, developed by Z.T. Bieniawski, used to characterize rock mass quality for engineering design, particularly in tunneling and rock slope stability analysis. We’ll cover the six input parameters, the calculation process, interpretation of results, and practical application, including support design guidelines. We’ll also touch upon available tools and resources, along with some advanced considerations.

Understanding RMR: A Rock’s Report Card

The RMR system assigns a numerical score to a rock mass, reflecting its overall quality and stability. This score is essential for engineers planning excavations, tunnels, mines, and slopes, informing decisions about support structures and construction techniques. A higher RMR suggests a stronger, more stable rock mass, requiring less extensive support.

RMR Parameters: The Six Key Ingredients

The RMR score is derived from six crucial parameters:

1. Uniaxial Compressive Strength (UCS): Measuring Rock Strength

This measures the maximum compressive stress a rock sample can withstand before failure. A higher UCS generally indicates a stronger rock. UCS is typically determined through laboratory testing.

| UCS (MPa) | Rating |

|---|---|

| > 250 | 15 |

| 100 – 250 | 12 |

| 50 – 100 | 7 |

| 25 – 50 | 4 |

| 10 – 25 | 2 |

| < 10 | 1 |

2. Rock Quality Designation (RQD): Assessing Intactness

RQD quantifies the percentage of intact rock core recovered during drilling. Higher RQD values suggest a less fractured, more intact rock mass.

| RQD (%) | Rating |

|---|---|

| 90 – 100 | 20 |

| 75 – 90 | 17 |

| 50 – 75 | 13 |

| 25 – 50 | 8 |

| < 25 | 3 |

3. Spacing of Discontinuities: Gauging Fracture Frequency

This parameter measures the distance between discontinuities (joints, fractures, etc.) in the rock mass. Wider spacing generally implies greater stability.

| Spacing (m) | Rating |

|---|---|

| > 2 | 20 |

| 0.6 – 2 | 15 |

| 0.2 – 0.6 | 10 |

| 0.06 – 0.2 | 8 |

| < 0.06 | 5 |

4. Condition of Discontinuities: Evaluating Fracture Characteristics

The condition of discontinuity surfaces—roughness, weathering, infilling—significantly impacts stability. Rough surfaces tend to interlock, enhancing stability, while smooth, clay-filled surfaces are prone to slippage.

| Condition | Rating |

|---|---|

| Very Rough | 30 |

| Rough | 25 |

| Slightly Rough | 20 |

| Smooth | 10 |

| Slickensided | 0 |

5. Groundwater Conditions: Assessing Water Influence

Groundwater can weaken rock and increase pore pressure, potentially destabilizing the rock mass. Drier conditions typically correlate with higher stability.

| Condition | Rating |

|---|---|

| Completely Dry | 15 |

| Damp | 10 |

| Wet | 7 |

| Dripping | 4 |

| Flowing | 0 |

6. Orientation of Discontinuities: Considering Fracture Direction

The orientation of discontinuities relative to the excavation direction can influence stability. Unfavorable orientations, where discontinuities are aligned with potential failure planes, reduce stability. This parameter often involves subjective assessment or stereographic projection techniques.

Calculating the RMR: Summing the Parts

The RMR score is calculated by simply adding the ratings assigned to each of the six parameters. Adjustments might be necessary for specific project geometry and discontinuity orientations.

Interpreting RMR: Classifying Rock Quality

The final RMR score translates to a rock mass quality classification:

| RMR Range | Rock Mass Quality |

|---|---|

| >80 | Very Good |

| 60-80 | Good |

| 40-60 | Fair |

| 20-40 | Poor |

| <20 | Very Poor |

Applying RMR: Guiding Support Design

Bieniawski’s guidelines link RMR classes to recommended support measures for tunnels, ranging from minimal support for “Very Good” rock to extensive reinforcement for “Very Poor” rock:

| RMR Range | Potential Support Needs |

|---|---|

| >80 | Minimal support (spot bolting) |

| 60-80 | Light support (systematic bolting, occasional shotcrete) |

| 40-60 | Moderate support (steel sets, more extensive shotcrete) |

| 20-40 | Heavy support (steel sets, concrete lining) |

| <20 | Very heavy support (extensive reinforcement) |

RMR Tools and Resources

Various tools simplify RMR calculations:

- Mobile Apps: Several apps provide convenient RMR calculation and data entry.

- Spreadsheets/Online Calculators: Numerous free and paid resources automate the calculation process.

- Geotechnical Software: Advanced software packages offer integrated RMR assessment alongside other analyses.

Advanced Considerations and Limitations

While valuable, RMR has limitations:

- In-situ stress: RMR doesn’t explicitly consider in-situ stress, a potential influence on stability.

- Subjectivity: Some parameters, like discontinuity condition and orientation, involve subjective judgment.

- Rock type influence: Rocks with similar RMR values can behave differently due to inherent material properties.

Other rock mass classification systems, such as the Q-system, may be more appropriate for certain situations. Ongoing research continually refines our understanding of rock mass behavior and classification methods. For critical projects, consulting experienced geotechnical engineers is essential.

Reference: Bieniawski, Z.T. (1989). Engineering Rock Mass Classifications. Wiley.

- How to Produce Free Energy for Your Home - February 11, 2026

- How to Generate Electricity for Free at Home - February 10, 2026

- How To Produce Free Electricity By Generating Your Own Power - February 9, 2026